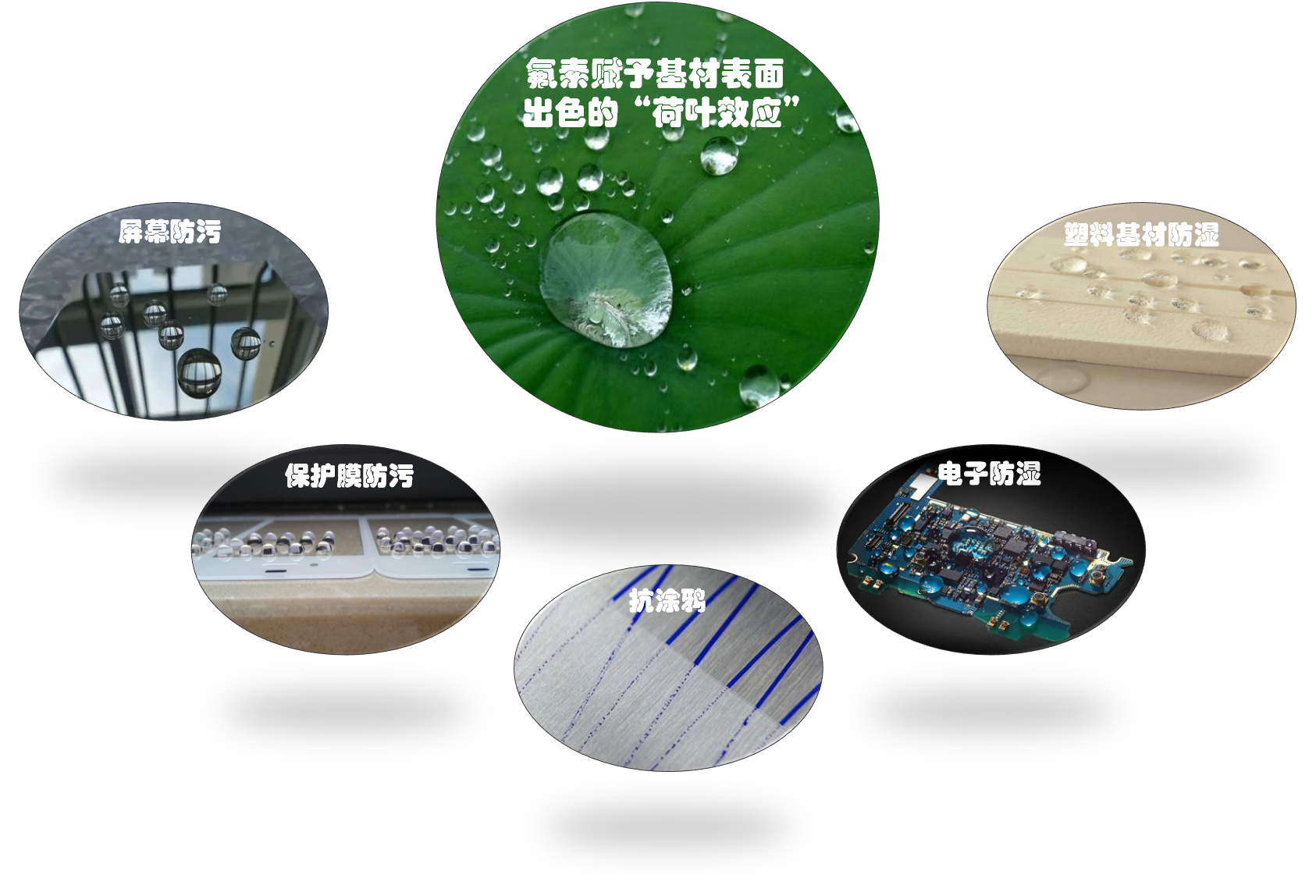

AF-UV2188 is an anti-fingerprint UV resin suitable for use in oil-based UV/EB curable coatings, with a small addition for excellent anti-fingerprint and anti-stain and anti-graffiti properties. It is a kind of anti-fingerprint function coating additives, can also be used as leveling agent, wetting agent and anti-fouling anti-graffiti coating additives. The product does not contain toxic fluorocarbon chemicals such as PFOS and PFOA, does not contain organic solvents, and has low odor.

AF-UV2188 | |||

Apparent | liquid | Solids | 100wt% |

The main ingredient contains | Fluorinated acrylic ester | Average functional degree | 5 |

Refractive index | 1.41 | Dynamic friction coefficient | 0.35 |

Oil contact Angle | 75° | Water contact Angle | 114° |

Additive amount | 0.5-5.0% (recommended) | ||

Applicable coatings | Oily UV/EB paint, oily UV hardening fluid | ||

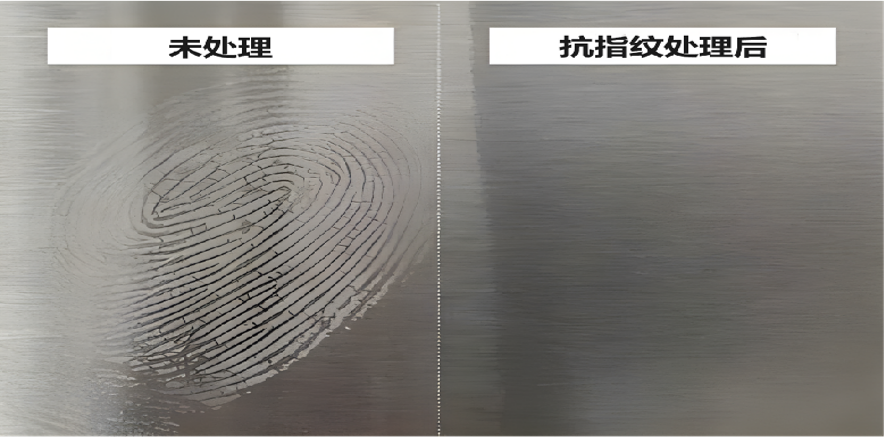

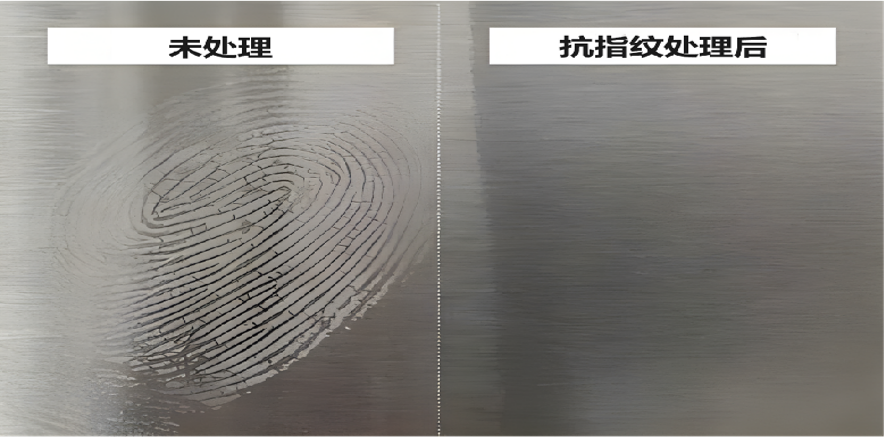

Basic characteristic | Give radiation curing coatings excellent anti-fingerprint function; Give radiation curing coatings excellent anti-fouling and anti-graffiti properties; Fuzi radiation curing coating excellent leveling and wettability; Reduce the friction coefficient of the paint film surface. | ||

Note: The above data is based on the typical values under the experimental conditions of the company, for reference only, not as a formal warranty commitment.

2. Application field

1) Protective coatings for 3C product shells, including mobile phones, tablets, laptops, white goods, portable game consoles, composite panels, etc.

2) hardening liquid of optical film, including mobile phone protective film, mobile phone protective case window, display film, eye lens, camera and other optical components;

3) Hardening coatings on other film surfaces, such as the hardening fluid on the substrate surface such as PC, PMMA and PET, and the hardening fluid on the surface of the optical disc;

4) UV curable release coating/paint.

3. Usage method

1) After the product is fully mixed and evenly with the existing paint, the film is made after standing and defoaming. Universal coating methods such as scraping, spraying or spraying can be selected;

2) Baking leveling, baking temperature 40~100℃, baking time 1~10min, the specific conditions can be adjusted according to actual needs;

3) photocuring film formation;

Note: There are compatibility problems between anti-fingerprint additives and different solvents, resins and additives in the coating system, and the anti-fouling performance is also different in different formulations of coatings, and the coating formulation needs to be adjusted if necessary to achieve the ideal anti-fouling performance.

4. Storage and operation

1) Stored in a low temperature and dark environment, the ambient temperature should not be higher than 30℃;

2) Do not swallow, inhale or touch;

3) Harmful gases will be produced during high temperature decomposition.

5. Packaging and storage

Packing: 1000g, 5000g, HDPE high clean bottle.

Storage: Please store in a cool, dry, ventilated, dark place, temperature not higher than 25℃.

Before formal use, users must test themselves to ensure that the product and its application can achieve the special purpose of users.

The Company shall not be liable for any use or usage which has not been formally stated to the Company in writing.