Loading...

Loading...

The semiconductor industry is one of the most important and rapidly-growing industries in the world. It’s responsible for billions of dollars in revenue each year, and it’s only growing larger. But what many people don’t know is that chemicals play a vital role in the semiconductor industry.

In this blog post, we’ll take a closer look at the role of chemicals in semiconductors and explore how they’ve helped make this industry one of the most successful in the world. Stay tuned!

The semiconductor industry is one of the most important and rapidly-growing industries in the world. It’s responsible for billions of dollars in revenue each year, and it’s only growing larger. But what many people don’t know is that chemicals play a vital role in the semiconductor industry.

In this blog post, we’ll take a closer look at the role of chemicals in semiconductors and explore how they’ve helped make this industry one of the most successful in the world. Stay tuned!

•What Are Chemical Semiconductors?

•Chemicals In The Semiconductor Manufacturing Process

•Electronic Chemicals For Manufacturing Semiconductor Devices

•Dry Etching

•Wet Etching

•Chemicals For Cleaning

•Chemical Mechanical Planarization (CMP)

•The Impact of The Semiconductor Market for Chemical Suppliers

•The Chemicals In The Semiconductor Industry

What Are Chemical Semiconductors?

Image of a microchip in a circuit board

The most important thing to understand is that there is nothing called chemical semiconductors. Instead, the global semiconductor industry exhausts the use of chemicals in semiconductor manufacturing processes to ensure that the materials and components are according to the parameters required.

Although there are no chemical semiconductors specifically, chemicals play a critical role in ensuring semiconductors are fit for their applications in the electronics industry, along with many other businesses and industries ranging from healthcare to automobiles, artificial intelligence, and whatnot. Below is everything you need to know about chemical usage in semiconductor processes.

Chemicals In The Semiconductor Manufacturing Process

Chemicals in a laboratory

There are various semiconductor chemicals used for diverse processes from etching the wafer surface to fabricating printed circuit boards (PCBs), and much more. Below are some of these chemicals explored in detail.

Electronic Chemicals For Manufacturing Semiconductor Devices

There are many electronic chemicals used in the high-tech industry of semiconductors that directly deal with the fabrication of semiconductor wafers, integrated circuits, compound electronic devices for semiconductors, and many more. Chemicals are used every step of the way from the photolithography process to thin films, doping, CMP, and even post-CMP cleaning.

The imminent introduction of smaller nodes, transistors, and other minute components in the semiconductor manufacturing industry is a testament to the need for chemicals as opposed to physics. These chemicals are required to precisely alter and transform the components to work effectively without losing their functionalities as it reduces in size.

These include chemicals like sulfuric acid, nitric acid, hydrogen peroxide, ammonium hydroxide, hydrochloric acid, phosphoric acid, and many others. Chemicals play a strategic importance in the process of etching, some of which we have mentioned below.

Dry Etching

In the case of dry etching, halogenated specialty gasses are administered into a plasma. The most commonly administered chemicals for dry etching are chlorine and 1,1-dichloro-1-fluoro ethane. Fluoride ions are used more often with silicon compounds while chlorides are administered for applications that use only silicon.

Wet Etching

Wet etching is a process that will be replaced by dry etching with time, due to the high precision of the latter, especially in its compatibility with small components. Regardless, wet etching is still ongoing and uses electronic chemicals that are solutions of acids, bases, and oxidizing agents. Hydrogen peroxide and sulfuric acid are two of the chemicals used most often in various processes from etching to cleaning.

That brings us to the next broad range of chemicals used to remove impurities and clean devices are the fabrication processes, wafer transferring, and the other processes involved.

Chemicals For Cleaning

The semiconductor industry has a high dependence on hydrofluoric acid which is used in the fabrication of silicon wafers and other silicon products. It is used in many aspects of the supply chain from acting on silicon dioxide to form a soluble compound to essential cleaning of materials, and removal of residual chemical products and oxides.

A high-concentration form of sulfuric acid is used to rid semiconductor materials of impurities. Silicon wafer rinsing agents and particle rinsing agents are just some of the few cleaning agents made from semiconductor chemicals.

One of the most important processes carried out with semiconductor chemicals is chemical mechanical planarization or polishing. We have explained it in detail below.

Chemical Mechanical Planarization (CMP)

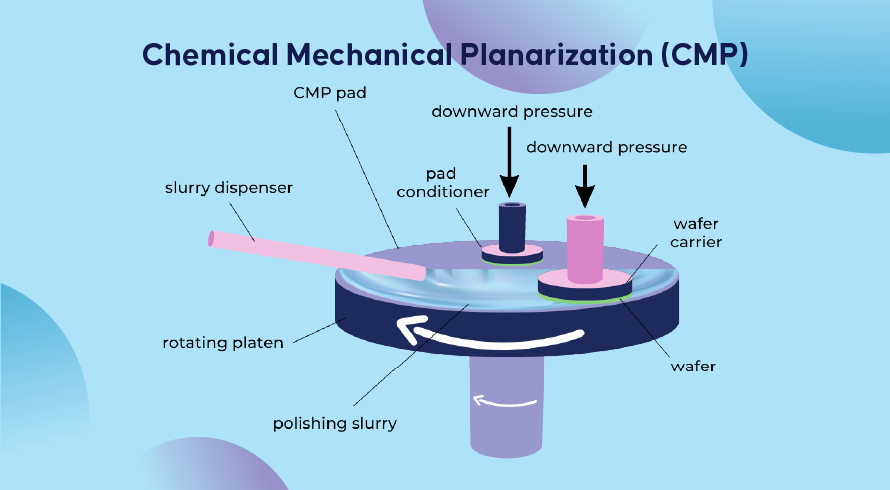

Chemical Mechanical Planarization (CMP) Process

Chemical mechanical planarization is a process that uses chemical and mechanical abrasion to ensure that electrical components like wafers achieve planarity and a flat edge that is essential for the smooth operation of integrated circuits and semiconductor devices.

The process uses CMP slurries which rid the top surface of the material of impurities or conduct wet-etching to ensure the thin films are laced with suitable materials. Chemical suppliers earn a bulk of their earnings from producing CMP slurries along with other chemicals used for CMP post-cleaning processes.

The Impact of The Semiconductor Market for Chemical Suppliers

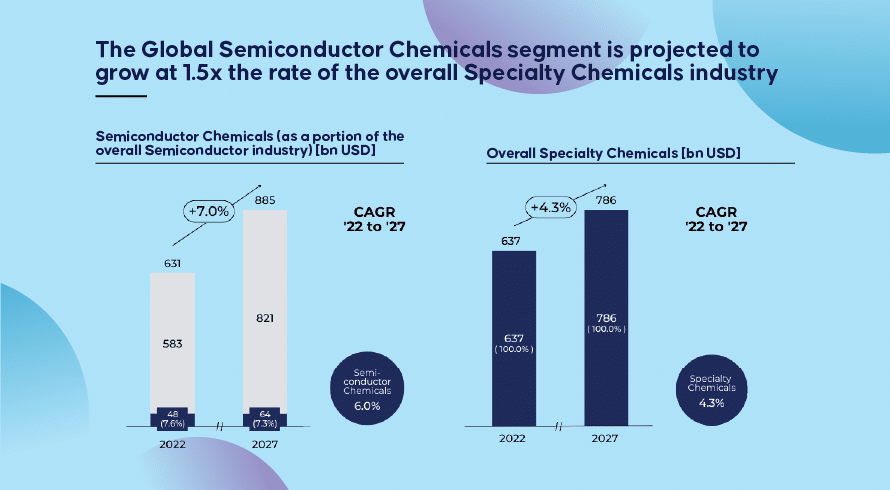

The expected growth of the Global Semiconductor Chemicals Industry

The requirement for chemicals to manufacture semiconductors has caused an impending need for chemical materials suppliers to produce them at a staggering rate. With a growth of 6% every year and 48% sales from the semiconductor industry, new fabs in Southeast Asia are taking on business opportunities to go up the value chain in producing semiconductor chemicals.

Countries like South Korea, Singapore, Taiwan, and mainland China are reshaping the industry, growing to occupy a larger market share as chemical suppliers. For businesses looking to enter the semiconductor manufacturing industry, chemical production can be a successful venture to dive into.

The Chemicals In The Semiconductor Industry

There are no chemical semiconductors but chemicals transform semiconductor manufacturing technology into a more profitable and highly effective business. It is important to ensure you have the right equipment, solid research, and trained professionals in the handling of any processes that require the usage of chemicals in fabricating semiconductors. Still, with adequate research and a team of professionals, this can be a great venture for chemical production companies due to the high demand for both chemicals and semiconductors.