Loading...

Loading...

I. Overview

Perfluom Polyethers (PFPE), first studied by polyethers in the 1960s, is a special type of perfluoro polymer with an average molecular weight of 500-15000 and only three elements: C, F, and O. It is resistant to heat, oxidation, radiation, corrosion and non-combustion, and has been used for decades as an extremely reliable lubricant in cutting-edge fields such as the military, aerospace and nuclear industries. Today, perfluoropolyethers are widely used in chemical, electronic, electrical, mechanical, nuclear industry, aerospace fields.

Second, synthesis method

According to the different monomers and polymerization methods used, four types of PFPE with different molecular structures including K type, Y type, Z type and D type can be obtained:

The first K-type structural formula is CF3CF2CF2O[CF(CF3)CF2O]nCF(CF3)COF. It is a series of branched-chain polymers formed by the polymerization of hexafluoropropylene oxide (HFPO) under the catalysis of CsF.

The second Y-type structural formula is CF3O(C3F6O)m(CF2O)nCF3. It is a polymer formed by photooxidation of hexafluoropropylene (HFP) under the action of ultraviolet light, and the molecular weight is generally between 1000 and 10000.

The third Z-type structural formula is CF3(C2F4O)m(CF2O)nCF3. It is a straight-chain polymer formed by photooxidation of tetrafluoroethylene (TFE) under ultraviolet irradiation, and the molecular weight is generally between 1000 and 100000.

The fourth type D structural formula is C3F7O(CF2CF2CF2O)mC2F5. It is a polymer obtained by direct fluorination of the polymerization product of tetrafluorooxane.

At present, there are two main synthesis methods of perfluoropolyethers: photocatalytic polymerization and anionic catalytic polymerization.

1) Photocatalytic polymerization

Italy Montefluos company takes tetrafluoroethylene or hexafluoropropylene as raw material, reacts with oxygen through ultraviolet irradiation at low temperature, and obtains polyether with slightly different structure through oxidation polymerization. Taking tetrafluoroethylene as an example, in addition to the acyl fluoride end group, there are also unstable peroxide groups in the main chain of the crude product structure, which need to be eliminated by heating or lighting, and then use the element fluorine to stabilize the end group. The method was commercialized in the 1960s under the brand name Fomblin (which has been incorporated into SOLVAY) and the molecular structure is Y type and Z type.

2) anionic catalytic polymerization

The anionic polymerization method is based on perfluoropropylene oxide (HFPO) as raw material, and the oligomers containing acyl fluoride end groups can be obtained by using fluorine ion as catalyst in aprotic solvent. The main products are Krypton produced by DuPont in the United States and Demnum produced by Daikin in Japan (Daikin perfluoropolyether technology has been authorized by 12 national patents), etc., the molecular structure is K-type and D-type, and the method was first commercialized in the 1970s.

Iii. Characteristics

Perfluorinated polyether molecules contain only C, F, O three elements, because fluorine atoms have a strong electronegativity, most of the carbon chain is shielded by fluorine atoms, and compared with hydrocarbon polyether has high density, low surface tension, low volatility, good viscosity-flow, non-flammable, good dielectric properties, good lubrication and other advantages, and can be well compatible with plastics, rubber, metal. Perfluoropolyethers belong to low molecular weight fluoropolymers, and their viscosity has a great relationship with molecular structure and average molecular weight. PFPE with larger molecular weight has low volatility, wide liquid temperature range and excellent viscometry temperature characteristics.

The chemical composition and structure of perfluoropolyethers determine that perfluoropolyethers have excellent chemical properties, and because the chemical structure of various perfluoropolyethers is relatively close, they also have similar chemical properties.

1) Chemical inertia

Perfluoropolyether is chemically inert to most corrosive chemicals such as acids, bases and oxidants, but some nucleophiles (such as ammonia), active metals (such as Na, K, Al, etc.) and Lewis acid can decompose perfluoropolyether and reduce its thermal stability.

2) Thermal oxidation stability

In the absence of an effective catalyst, perfluoropolyether is stable in the range of 270-300, even in the presence of oxygen. The decomposition temperature can reach 350-410. The presence of some catalysts or inhibitors can change the thermal stability limit and degradation rate of perfluoropolyethers. If oxygen and some metals (or metal oxides, fluoride) are present, the degradation temperature of perfluoropolyethers generally drops by about 50. At the same time, the general straight-chain polyethers have better thermal oxidation properties than those with branched chain structure. The use of stabilizers (such as arylamines, benzimidazole derivatives, and selenides) can prevent or ameliorate the effect of metals on perfluorinated polyether oils at high temperatures.

3) Compatibility

Perfluoropolyethers are compatible with many substances, such as oxidants (hydrogen peroxide, liquid oxygen, etc.), hydrocarbon fuels, undimethylhydrazine, diethyltriamine, etc. Y-type and Z-type perfluoropolyethers have good compatibility with plastics and artificial rubber.

4) Fire resistance

Fire resistance is an important condition for the application of perfluoropolyethers in industrial and aviation lubricants. Compared with other types of lubricants, perfluoropolyethers are more suitable for high temperature and harsh operating environments.

5) Radiation resistance

Perfluoropolyether has better radiation resistance, and the viscosity growth rate is the lowest compared with hydrocarbon and silicone oil at the same dose.

Iv. Application

Perfluoropolyether materials are mainly used in special lubricants, industrial fluids, functional chemicals, etc., the specific application fields are:

1) Aerospace industry

Perfluoropolyether is suitable for the lubrication and sealing of power systems and space-exposed mechanical systems such as engines, thruster bearings, longitudinal adjusters, power wheels, scanning mirrors, gear pumps, pressure gauges, metal joints and threaded fittings.

2) The nuclear industry

Perfluorinated polyether is suitable for bearing lubrication of ultra-centrifuges in nuclear industrial facilities and is the only material that can resist the corrosion of uranium hexafluoride at 130 ℃.

3) Electronic and electrical industry

Perfluoropolyethers are suitable for the lubrication of mechanical vacuum pumps in a variety of semiconductor integrator production processes such as plasma etching, chemical vapor deposition and ion insertion, and are also used as lubricants on hard drives, disks and other magnetic recording media in electronic instruments.

4) Chemical industry

Perfluoropolyether can be used as a working fluid medium for various vacuum pumps (such as rotary pumps, turbolecular pumps, steam diffusion pumps) (especially in the presence of corrosive gases), and as a lubricating material for compressors and valves in contact with liquid oxygen, oxygen, corrosive and oxidizing gases.

5) Other industries

Perfluoropolyether is also widely used in oxygen industry, mechanical and electrical industry, automotive industry and mechanical lubrication under various extreme working conditions of high temperature, high load and high corrosion.

6) Perfluoropolyether derivatives

The acyl fluoro terminal group in the structural formula of the acyl fluoro oligomers prepared by perfluoropropylene oxide (or tetrafluorooxacyclobutane, etc.) has high reactivity, which can be further reacted into various derivatives, and corresponding fluorocarbon surfactants are synthesized. The non-polar group has not only hydrophobic properties but also unique oleophobic properties, and such surfactants have extremely high surface activity and stability. At very low application content, it can significantly reduce the surface tension of aqueous solution, and has the characteristics of directional adsorption and formation of micelles in solution, which can be used as emulsifier in emulsion polymerization. When the molecular weight of the polymer is not too high, it can prevent monomer droplets or polymer particles from approaching association and produce condensation, so as to stabilize the dispersion system. In practical application, this kind of surfactant also has good solubility. Due to the advantages of special performance, small dosage and non-toxicity, this kind of surfactant is a kind of product with high technical content and high added value, and has broad development and application prospects.

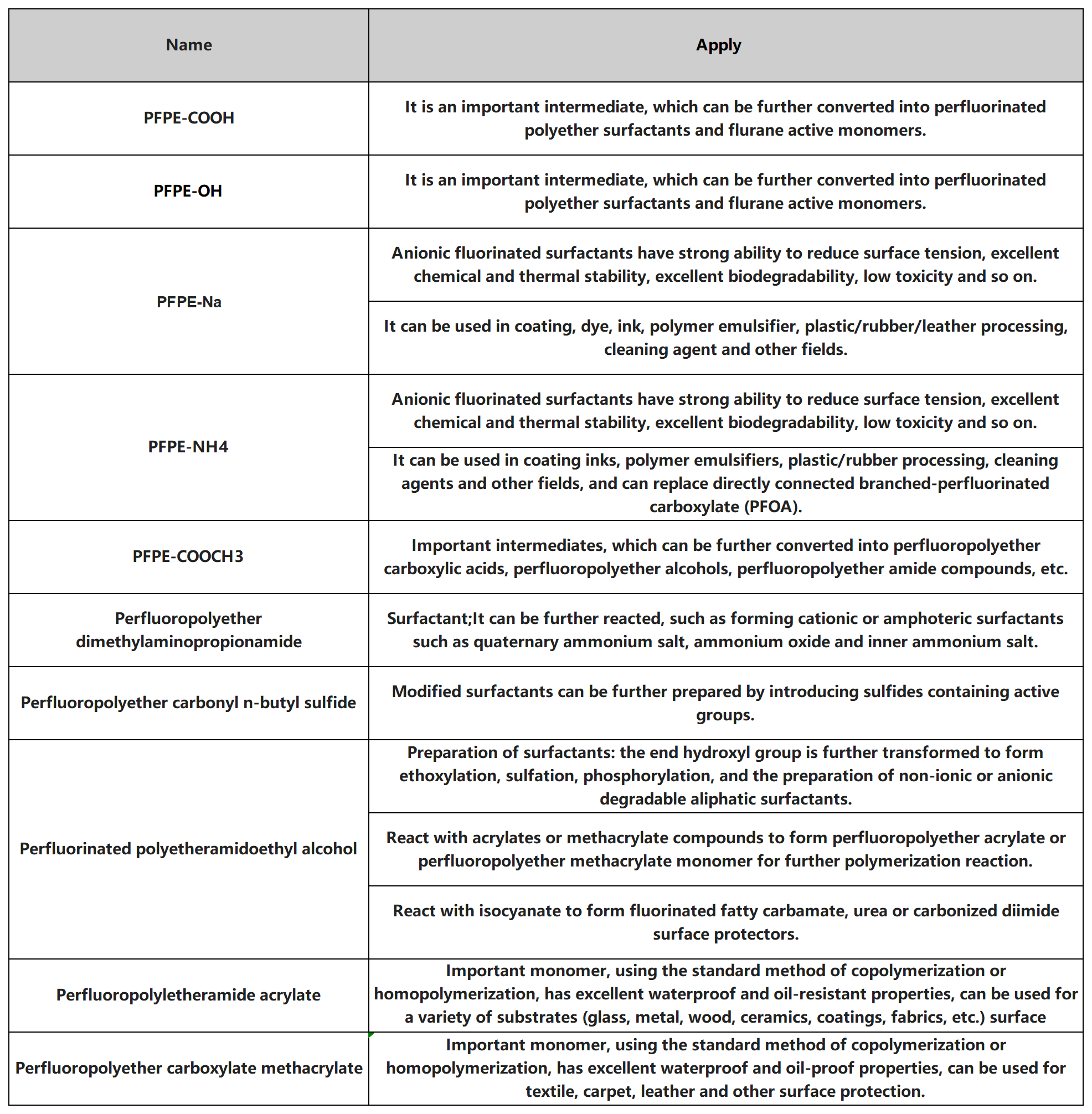

Some perfluoropolyether derivatives and their applications

5. International market

5. International market

At present, the main foreign manufacturers of perfluoropolyether products are DuPont, Suwei, Daikin. In addition, international lubricant manufacturers such as Shell, ExxonMobil, Dow Corning, 3M, NYE, Klub, IKV Tribology, JETLUBE and so on have commercial products of perfluorinated poly (ether) oil.

In the case of DuPont, Kryptox products are divided into seven families:

(1) Kryptox GPL General purpose series: 204, 205, 206 and other brands are quoted at about $500 /kg.

(2) Kryptox vacuum pump oil series: 1505, 1506, 1525 and other brands are quoted at $250 /kg.

(3) Kryptox VPF high vacuum lubrication seal grease: quote about 1400-1500 US dollars /kg.

(4) Kryptox aerospace, military industry special oil: 143, 240, 283 and other grades quoted 2000-2500 US dollars /kg.

(5) Kryptox EG electronic grade grease series: EG2000, EG3000 and other brands quoted at 1400 US dollars /kg.

(6) Kryptox XHT ultra-high temperature series: especially for high temperature bearings, the maximum service temperature of 400, a variety of brands offer 700-1500 US dollars /kg.

(7) Krytox food-grade lubricating oil: It can be applied to the medical and food machinery industries. The Corrugator 226/227 FG product is quoted at $220 /kg.

Taking Solvay as an example, perfluorinated polyether products are divided into five series

(1) Fomblin PFPE YL-VAC vacuum pump oil series: the price is about 200-300 US dollars /kg, and the domestic agent Shenzhen Synthetic Materials Company offers 2000 yuan /kg.

(2) Galden Heat Transfer Fluid: According to different boiling points (55-270) divided by multiple product grades, HT55, HT70, HT80, HT110, HT135, HT170, HT220, HT230, HT270, the price is about 110-160 US dollars /kg.

(3) Galden PFS solvent series: can be used for electronic, semiconductor cleaning, can also be used for diluting viscous fluids, PFS-1, PFS-2 models.

(4) Galden Testing Electronic Fluids: applied to cold and thermal shock test and air tightness test in semiconductor and electronic packaging industry, there are D02, D03, D05, DET and other models, the price is about $90-120 /kg.

(5) Galden LS/HS gas phase welding liquid: can be used in semiconductor, electronic industry gas phase welding, LS200, LS215, LS230, HS240, HS260 models, the price is about 110 US dollars /kg.