Loading...

Loading...

First author: Nanyang Yang & Shasha Yang

Corresponding author: Yang Yang

Correspondence: Department of Civil and Environmental Engineering, Clarkson University

Solvent-free, non-thermal destruction of PFAS in PFAS chemicals and sediments by piezoelectric ball milling.

English title: Solesolvent -Free Nonthermal Destruction of PFAS Chemicals and PFAS in Sediment by Piezoelectric Ball Milling.

Summary and detail

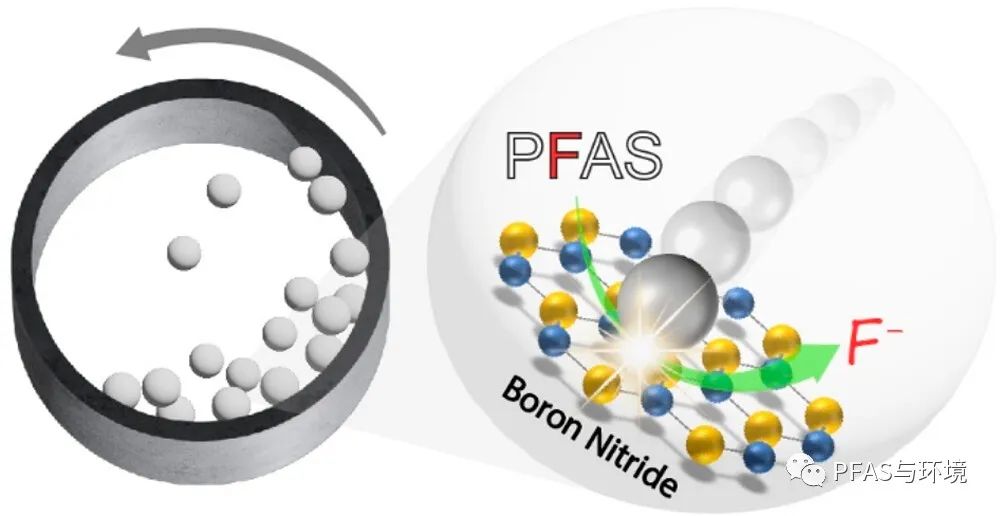

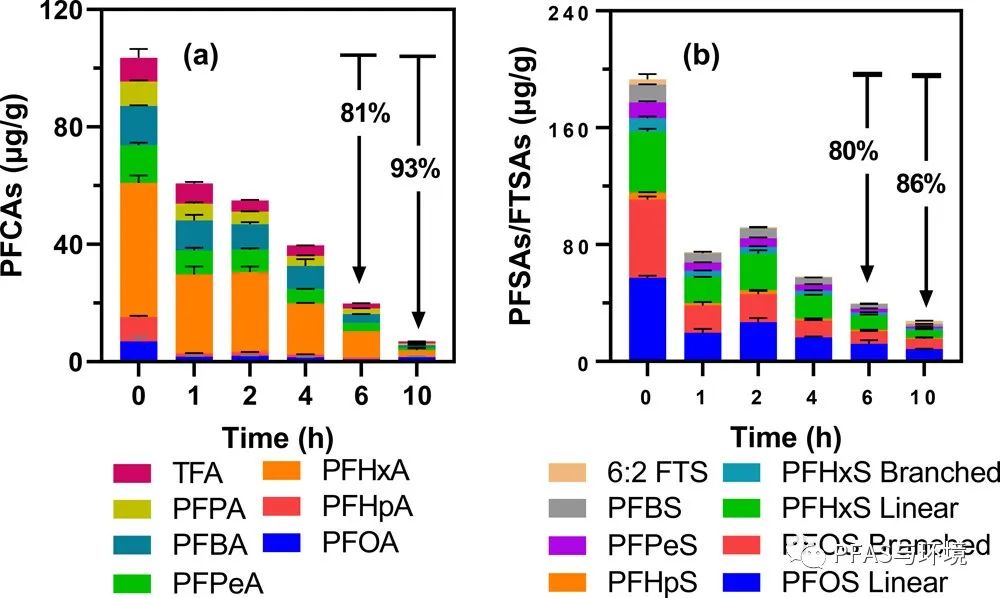

Research on the destruction of solid perfluorinated and polyfluoroalkyl substance (PFAS) chemicals and solid waste containing PFAS lags far behind urgent social needs. There is an urgent need to develop new treatment processes that can destroy non-aqueous PFAS at ambient temperatures and pressures. In this study, we developed a piezoelectric material assisted ball milling (PZM-BM) process based on the principle that ball collisions during grinding can activate PZM, producing a kV class PFAS destruction potential in the absence of solvents. Using typical PZM boron nitride (BN) as an example, we successfully demonstrated that solid PFOS and perfluorooctanoic acid (PFOA) were completely destroyed and nearly quantitatively (~ 100%) defluorinated after 2 hours of treatment. The process is also used to treat PFAS-contaminated sediments. After 6 hours of treatment, about 80% of the 21 targeted PFAS were destroyed. The reaction mechanism was determined to be a combination of piezoelectric electrochemical oxidation of PFAS and fluorination of BN. The PZMBM process demonstrates many potential advantages because the degradation of multiple PFAS is independent of functional groups and chain structure, and does not require corrosive chemicals, heating, or pressurization. This groundbreaking study lays the foundation for optimizing PZM-BM for the treatment of various PFAS-rich solid wastes.

Graphic abstract

Article introduction

Non-incineration methods for treating solid PFAS include ball milling (BM), hydrothermal liquefaction, and alkali-assisted decomposition. Of these technologies, only BM can handle solids directly at room temperature and pressure without the need for solvents. To date, selected pure PFAS compounds (PFOS, PFOA, 6:2FTS, etc.) have been shown to work with different co-grinding reagents (CaO, KOH, Al2O3, La2O3, ferrate, persulfate, and SiO2). KOH is the only co-grinding reagent that achieves fluorine conversion of about 90% from PFOS to F−. Although these pioneering efforts laid the technical foundation, remaining challenges must be addressed: (1) The KOH assisted ball milling (KOH−BM) process requires excessive chemical doses, and the treated caustic solids require modification prior to discharge/reuse. (2) Ambient humidity and moisture cause the KOH powder to caking, thus delaying the reaction. (3) Most studies have been limited to treating pure PFAS chemicals, although they have recently been implemented for treating PFAS sharp sand and contaminated soil. There is an urgent need for alternative co-grinding reagents that are as effective as KOH in PFAS destruction and defluorination, while eliminating all associated limitations. In this study, we report on a groundbreaking piezoelectric material assisted BM (PZM-BM) process that demonstrates effective destruction and nearly 100% defluorination of gram solid PFOS and PFOA. More importantly, the new process has achieved good results in treating PFAS-contaminated sediments.

Graphic content

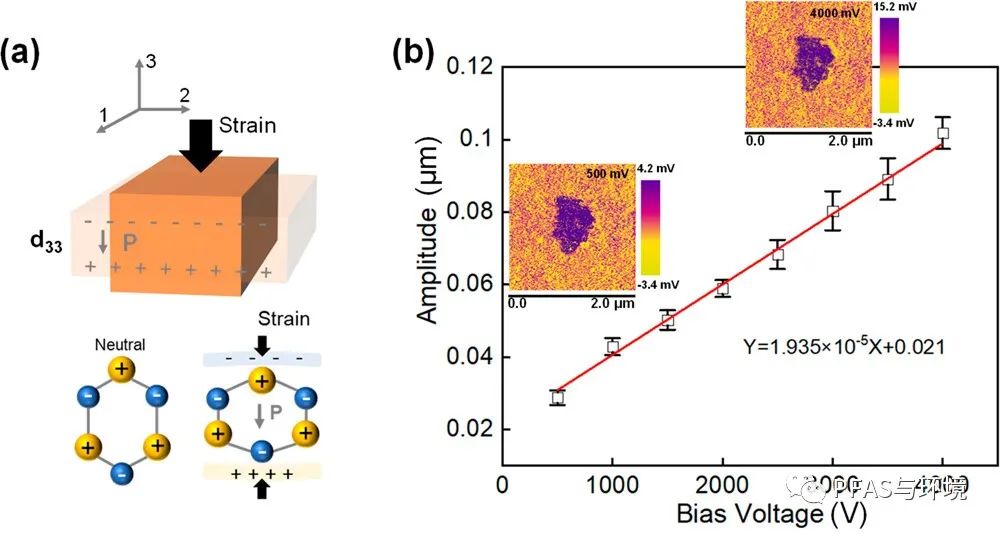

Figure 1. (a) Principle of piezoelectric effect. PZM crystals contain cations and anions. The overall charge of a cell battery is neutral. During deformation caused by mechanical strain, the cation moves downward while the anion moves upward. The misalignment of the positive and negative charge centers results in negative net charge and positive net charge at the top and bottom of the crystal cell, respectively. (b) PFM analysis of the piezoelectric response of BN under normal force impact.

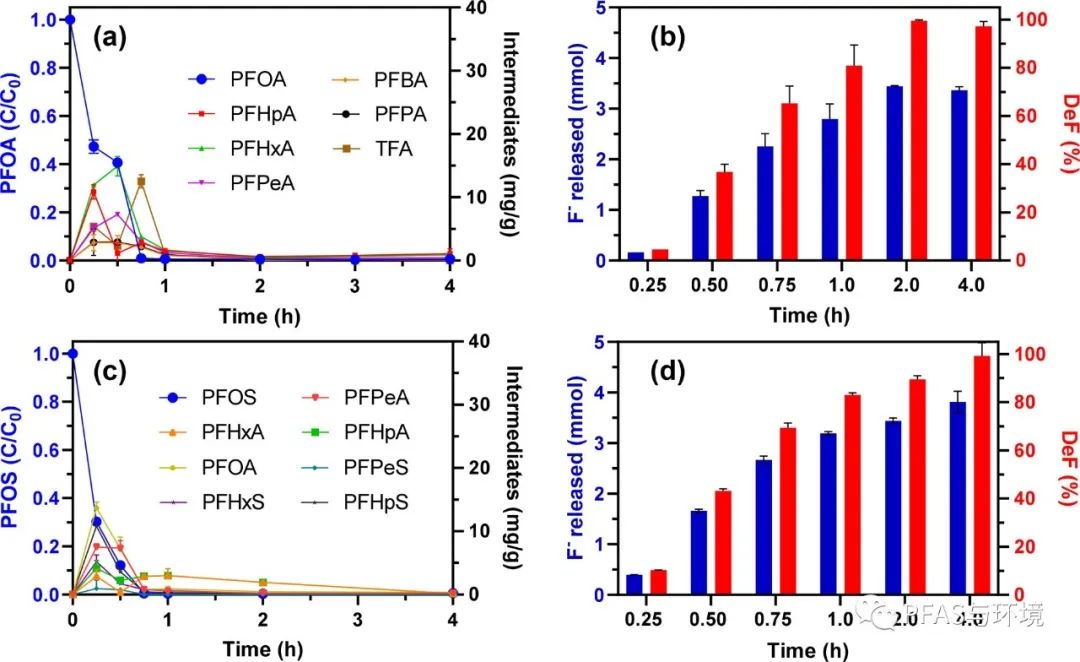

Figure 2. Destruction of (a) PFOA and (c) PFOS and formation of short-chain intermediates. Near-quantitative defluorination of (b) PFOA and (d) PFOS after ball milling.

Figure 3. Failure curves of (a) PFCA and (b) PFSA/FTS in sediments when BN is used as a co-grinding agent.

Key finding

It is important to emphasize that BN, like many PZMS, is a semiconductor. Previously, BN was reported to be reactive to PFOA degradation in a water-based photocatalytic reaction. However, there is no evidence that BN as a photocatalyst can destroy PFSA (e.g., PFOS). Here we successfully demonstrate that BM-activated BN can destroy PFSA. The results show that mechanochemical activation can confer greater REDOX capacity on BN and possibly other PZM than the photocatalytic pathway. The broader impact of this pioneering study is to validate the superior performance of the piezoelectric BM process in treating PFAS in sediments. This proof-of-concept opens various avenues for subsequent basic research on other piezoelectric materials and new applications for the treatment of PFAS-containing solid wastes (soils, commercial products, adsorbents, etc.).