Name: Perfluoropolyether oil; PFPE oil

CAS number: 60164-51-4

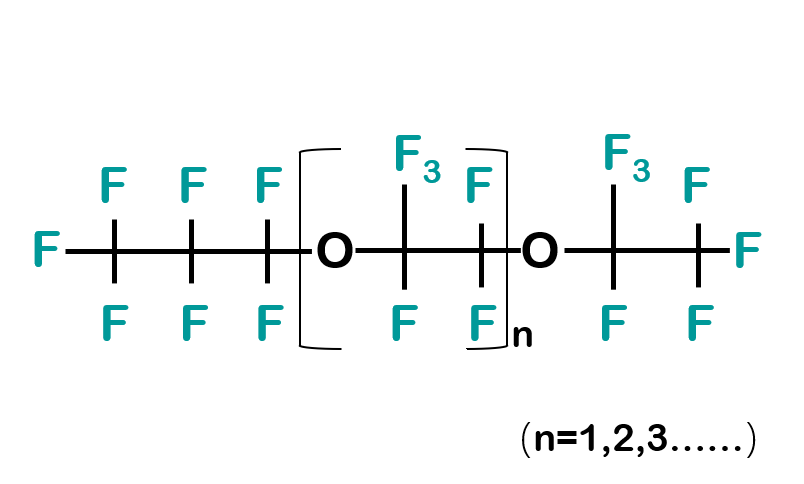

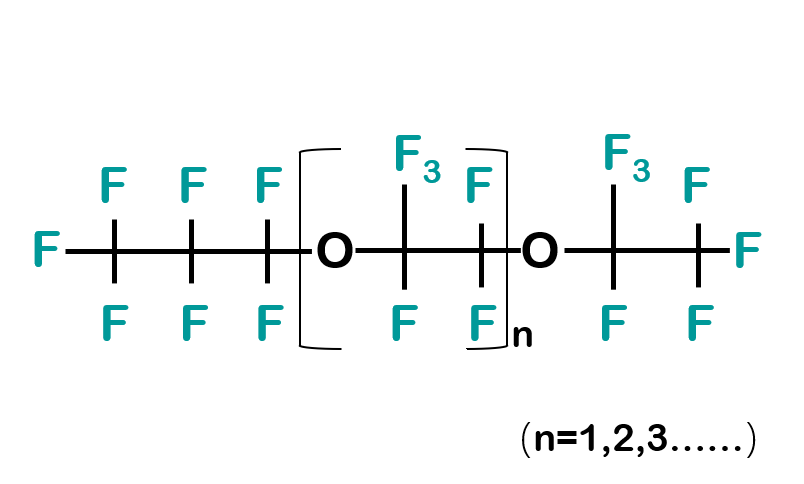

Molecular formula:F(CFCF3CF2O)nCF2CF3

Density: 1.72-1.98g /ml @ 20℃

Purity:≥99%

Appearance: Colorless transparent viscous liquid

Average molecular weight: 500 ~ 15000 g/mol

Packing:1KG;5KG;25KG;50KG;100KG;200KG

Application:

Perfluoropolyethers (PFPE) are a special class of perfluorinated polymer compounds, whose average molecular weight ranges from 500 to 15000, with only C, F, and O elements in the molecule. It has excellent physical and chemical properties, such as high temperature resistance, oxidation resistance, non-combustion, non-volatile, non-toxic, low pour point, low surface tension, excellent dielectric and lubricating properties, chemical inertness and biological inertness. Perfluorinated polyether oil is mainly used in heat, chemicals, solvents, corrosion, toxicity, flammability, and working environments with lubricating life requirements, and can also be used in chemical, electronic, military, nuclear, aerospace, and other lubrication fields with special requirements.

Thermo-oxidation stability: In the absence of catalyst, even in the presence of oxygen, PFPE is still very stable in the range of 270 ~ 300 ℃, and the obvious decomposition temperature can reach 350 ~ 550℃.

Chemical inertia: PFPE does not react with most corrosive chemical reagents such as inorganic acids, inorganic bases, organic acids, organic bases, halogens and oxidants, showing strong chemical inertia.

Compatibility: PFPE has good compatibility with many substances, such as fuel, plastic, rubber, metal, paint, etc., so the application range is very wide.

Non-flammability: More suitable for high temperature and harsh operating environments than other types of lubricants.

Dielectric properties: Perfluoropolyether has excellent dielectric properties, high dielectric strength, high resistivity and low dielectric constant.

Physiological inertia: Perfluoropolyether has no toxic effect on human organs, and through animal oral and skin contact tests, perfluoropolyether is low toxic and has no bad effect.

Low volatility: at the same viscosity, perfluoropolyether has a much lower vapor pressure than hydrocarbon lubricants, and the evaporation loss is small, ensuring a longer trial time.

Excellent friction performance: the base oil of perfluoropolyether grease has good lubrication ability, and the inorganic film-organic double layer film formed by perfluoropolyether on the surface of steel is an important reason for its wear resistance. Because the organic film formed belongs to the elastohydrodynamic lubrication film, it can reduce the direct contact between the friction pairs, thus reducing friction and wear; The wear marks on the steel surface are covered with a double layer film of metal fluoride and polymer. The fluoride film on the wear marks is a boundary lubrication film, which can reduce the friction coefficient